Enhancing Product Test Management by Using Digital Twins for Device under Test Analysis

New paths for product lifecycle management methods and IT tools appeared throughout traditional products evolving to smart products due to recent innovations in information and communication technologies. While some led to new, disruptive solutions, for example, reconfigurable smart products during their use phase based on digital twins, some others support or even enhance existing product lifecycle activities. Focusing on the latter, this contribution introduces how digital twins can be used in early product development phases to support the testing and subsequential evaluation of prototypes. Therefore, a test management approach is described that allows the integration of digital twins of devices under test, following a systematical exploration of their potential benefit on real-time analysis during and after the test run. The results were prototypically implemented by modeling a test environment in a product lifecycle management tool, including managing and analyzing digital twins of product instances.

This publication is the result of the research work of CONTACT Software Ltd. in Bremen.

Test Management and Digital Twins

Test management is a method dedicated to the organization of test assets and artifacts, such as test plans, test cases, and test results to enable accessibility and reuse [1]. Overall, three different types of testing can be distinguished: intuitive testing, testing based on design documents and requirements-based testing. In intuitive testing, the developers develop a prototype, which is tested by an unstructured approach, first by themselves and then by the end user. Design document-based testing begins by collecting documents so that tests can be performed by function in a logical order. Requirements-based testing is a further development of the first two testing methods and focuses on ensuring that the customer’s specifications to the product are met.

The concept of digital twins describes the virtual image of a physical asset [14] by reflecting its physical state in a current, historicized form [15]. Crucially, the digital twin is the link between field data, service information, analysis models, and development data, and thus bridges the gap between product development, production, and product use by connecting data along the digital thread [15].

Concept

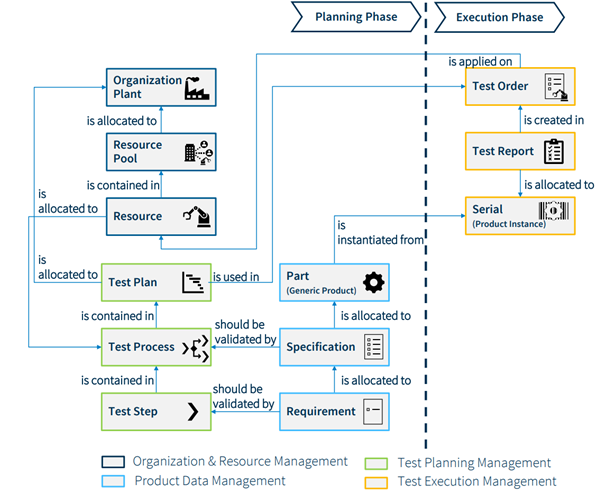

Test management relies on the management and provision of data objects that are part of the product lifecycle, particularly the product development phase. Thus, the product lifecycle management software CIM Database can provide all necessary data objects for a test management environment as part of the CONTACT Elements platform and will be used as a basis for the conceptional architecture. As introduced in chapter 2, some data objects can be allocated in the test planning or the test execution phase. These two phases can be found in figure 1.

Figure 1: Test Management Model

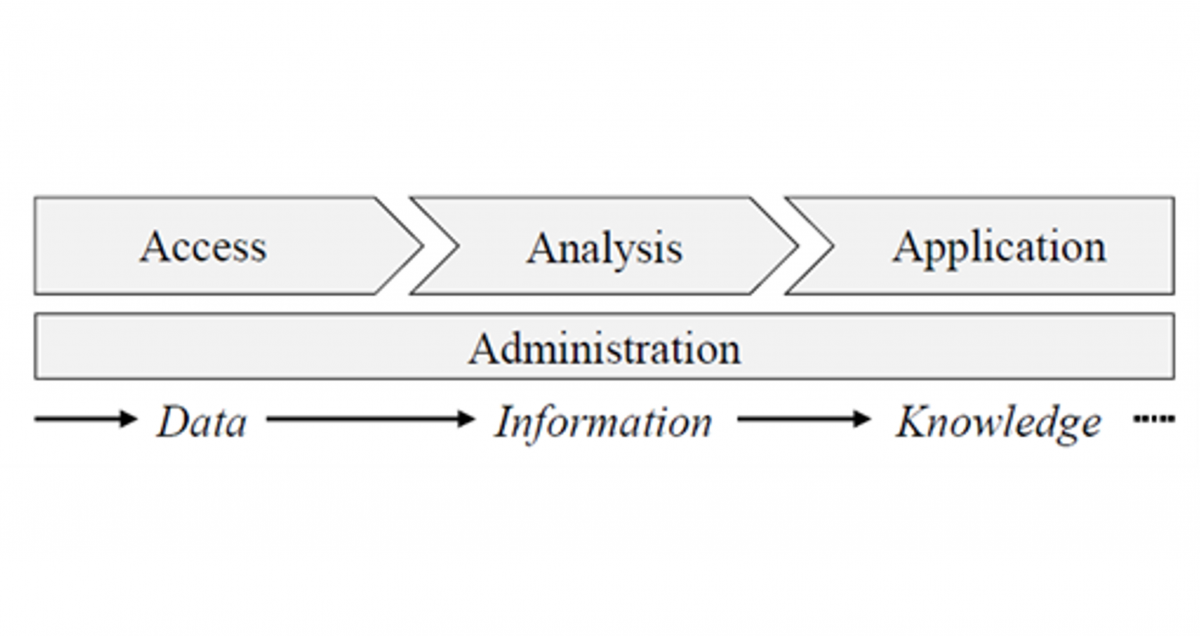

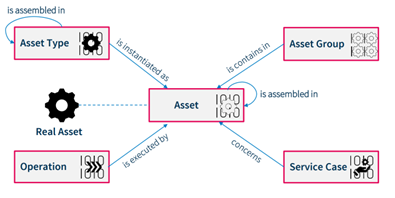

The digital twin links static and dynamic product data via the digital thread as a link between the development, production, and operation of a product. Consequently, the digital twin is not just part of the IT infrastructure, but is itself an object of development and an integral part of an interdisciplinary perspective on the product. [15] The Management of the digital twins, their data and business logic is realised with the software solution CONTACT Elements for IoT (CE4IoT), developed by CONTACT Software. The IOT Data Model used in there can be found in Figure 2.

Figure 2: IoT Data Model

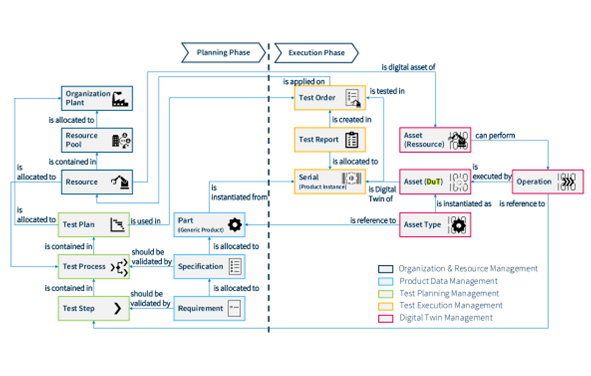

The main objects related to an IoT-based enhancement of test management are the asset (digital twin), the asset type (digital master), and the operation, as shown in Figure 2. The asset type is referring to the generic product object part. It can be considered the master template of each asset, which will be generated for each product instance object tested. The asset is the digital twin of the product instance (serial) that is under test. It consists of the real physical object’s prototypical configuration to be tested, including features, component structure, settings, operating status, usage, and environmental data. Out of the asset resource, operations of the device under test‘s asset can be performed. As time-limited processes of the asset usage, they can be considered digital references to test steps. They support test steps regarding each step of the test plan’s measuring process and create and log operations automatically, such as test results for each test step. Figure 3 shows the concept for IoT-enhanced test management.

Figure 3: Concept for an IoT-enhanced Test Management

[14] Abramovici, M. et al.: Reconfiguration of smart products during their use phase based on virtual product twins. CIRP Annals 66 (1), pp 165–168 (2017)

[15] Göckel, N. & Müller, P.: Entwicklung und Betrieb Digitaler Zwillinge. ZWF – Zeitschrift für wirtschaftlichen Fabrikbetrieb – Digitaler Zwilling. Hanser, Band 115, pp 7-10 (2020)

Implementation and Evaluation

To validate the conceptional architecture introduced in chapter 3, a prototypical system for a test management system, based on the CONTACT Elements technology, has been implemented. It consists of test management and necessary IoT-functionalities to allow real-time analysis of the devices under tests. In the given demo scenario, a washing machine was chosen as the device under test as it can be tested with different test steps that each include different possibilities for sensor analysis.

Conclusion and Outlook

Enhancing product test management by using digital twins enables fundamental new potentials for the device under test analysis, e.g., during the test as part of the real-time analysis and the instance-specific device management after tests have been executed. This contribution addressed this potential by describing fundamental approaches in both test and digital twin management at first. Subsequently, a conceptional architecture of a test management system and digital twins based on the CONTACT Elements technology have been introduced. Combining these two architectures shows how the test execution phase enriched by digital twins can qualify the device under test analysis in real-time and what dependencies between test management and digital twins need to be considered.

This research and development project is funded by the German Federal Ministry of Education and Research (BMBF) within the “Innovations for Tomorrow’s Production, Services, and Work” Program and implemented by the Project Management Agency Karlsruhe (PTKA). The author is responsible for the content of this publication.

The complete publication can be found here: