Rediscovering Scientific Management -The Evolution from Industrial Engineering to lndustrial Data Science

lndustrial Engineering (IE), through its role as design, planning and organizational body of the industrial production, has been crucial for the success of manufacturing companies for decades. The potential, expected over the course of lndustry 4.0 and through the application of Data Analytic tools and methods, requires a coupling to established methods. This creates the necessity to extend the traditional job description of lndustrial Engineering by new tools from the field of Data Analytics, namely lndustrial Data Science. Originating from the historic pioneers of lndustrial Engineering, it is evident that the basic principles will remain valuable. However, further development in view of the data analytic possibilities is already taking place. This paper reviews the origins of lndustrial Engineering with reference to four pioneers, draws a connection to current day usage, and considers possibilities for future applications of lndustrial Data Science.

This publication is the result of the research work of the Institute of Production Systems at TU Dortmund University.

Basics

The roots of IE can be traced back to Frederick W. Taylor, whose major work Principles of Scientific Management was instrumental in the development of industrial manufacturing (Taylor, 1911). The term IE encompasses all tasks concerned with the design, improvement, and installation of integrated systems of people, materials, information, equipment, and energy. It draws on specialized knowledge and skills in the mathematical, physical, and social sciences along with the principles and methods of engineering analysis and design to specify, predict, and evaluate the outcomes to be achieved by such systems, according to the Institute of Industrial and Systems Engineers definition (IISE, 2021).

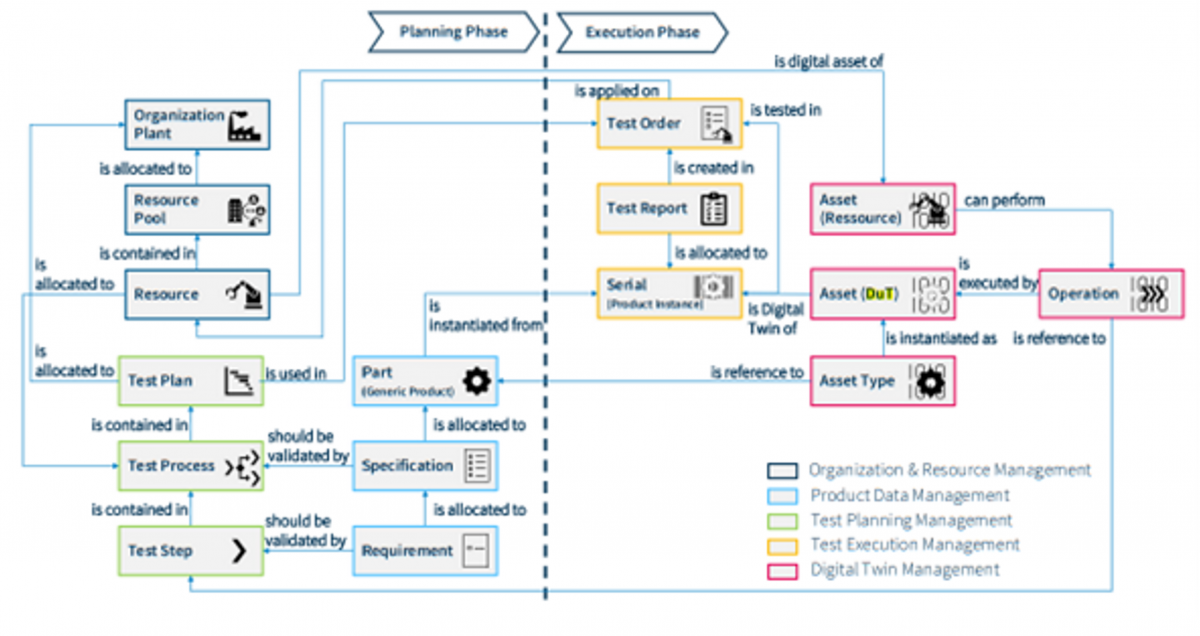

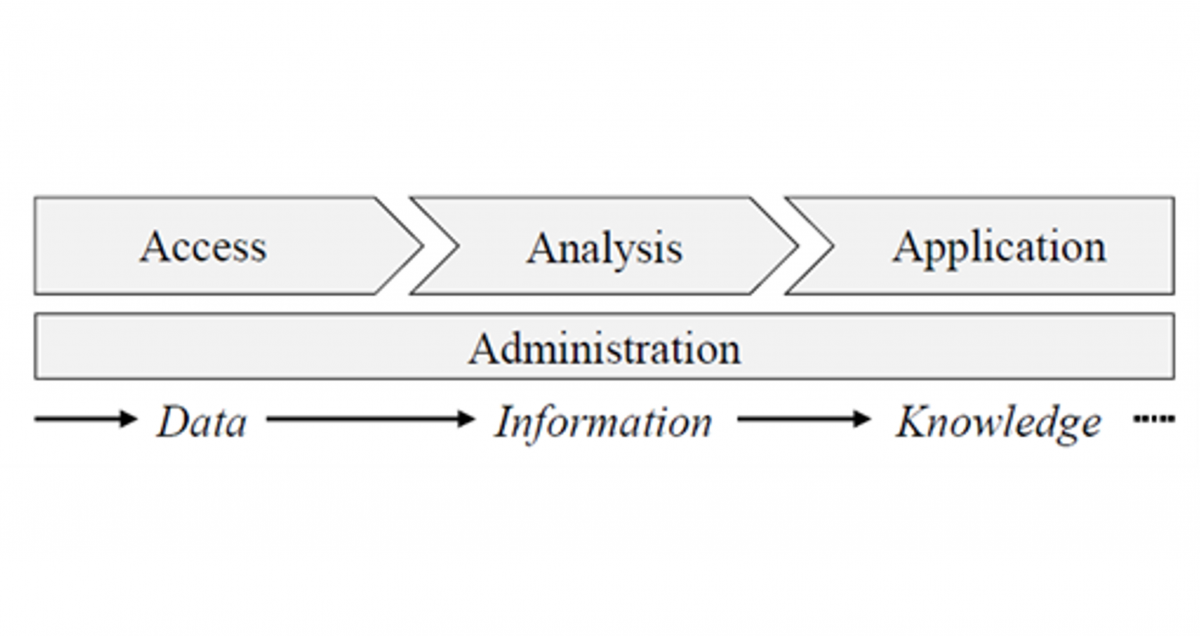

The field of data analytics has gained increasing attention in recent years. IDS refers to the use of data analytics in industrial applications (Mazarov et al., 2019). The application of these methods and techniques in today’s industrial environment is both effective and inevitable. This is due to the increased complexity in decision making as more variables need to be considered in today’s systems. IE and IDS involve closely related tasks for fact-based decision making. With the time management process chain, all activities for fact-based decision making are broken down into subtasks and processed sequentially. This has led to the development of the data analysis process chain, which follows a similar approach. The tasks of data collection, analysis, use and management are carried out in four stages (Figure 1).

Figure 1: Process chain of industrial data analysis

Pioneer Case Studies

These four Pioneer Case Studies include the Time and Motion Study by Frank and Lillian Gilbreth, the Group Technology by John Burbidge, the Quality Management by William E. Deming and the Production Control by Eliyahu M. Goldratt.

The four case studies are listed in a structured manner. The basic statements of the respective pioneers are listed in the “Past” section. In the “Present” section, the current approaches and technologies in this area are examined and listed. In the last section, “Future”, trends are listed and presented which are essentially based on the basic explanations of the pioneers. These current research topics include the combination of promising methods and tools, such as machine learning, with the principles from the past with reference to current approaches and technologies.

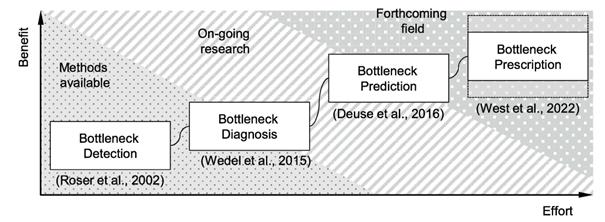

As an exemplary transfer of fundamental considerations into a future research trend, the development of bottleneck analysis can be mentioned, which can be overviewed in Figure 2.

Figure 2: Methodology for Bottleneck Analysis with corresponding research based on West et al. (2022)

Discussion

The development of the individual fields of industrial engineering shows the strong connection to data analysis from the beginning. The pioneers mentioned, Gilbreth, Burbidge, Deming and Goldratt, proved the dependence of optimization and improvement on data analysis. The present solutions prove the relevance of this approach equally. Industrial Data Science is therefore the logical evolutional step of working with data in Industrial Engineering. Many manufacturing companies face much more complex and complicated problems in parallel. For these companies, we consider Industrial Data Science as a novel tool that enables them to utilize the original ideas of the four pioneers in a more efficient, large scale and goal-oriented fashion. Tue different fields of IE need to be differentiated in this context. Every company uses the ideas of Gilbreth, Burbidge and Deming, in many productions they are even the basis of optimizations and the continuous improvement process in different sectors. The methods of Industrial Data Science extend the previous procedures making them reach the next stage of their development. Image recognition enables fast, accurate time recordings, machine learning enables the automatic creation of work plans of products of the same group and product and process quality can be dynamically detected, predicted and thus predictively improved in real time.

Conclusion and Outlook

The case studies of the pioneers of IE have shown the development of Scientific Management in four different domains as a rather evolutionary process. The contemporary trend towards a more widespread application of Industrial Data Science is an inevitable result of a decade-spanning development process. Leveraging the growing data sources is merely the next logical step in an environment that relies on fact-based and quantified decision-making. Thus, the application of Data Science in Industrial Engineering under the umbrella of Industrial Data Science will continue to grow in importance in the coming decades. At their core, manufacturing companies will continue to use the original concepts of the discussed pioneers but increase the effectiveness through the addition of digital and data-driven methods and tools, even in other fields of Industrial Engineering. Accessing, analyzing, applying and administrating data is going to be vital for future applications of Industrial Data Science. The pioneers presented in the paper, as well as their associated research areas, were selected primarily due to their high relevance to IE. Nevertheless, these representatives have to be called a selection of pioneers. In the continuing development of Scientific Management since Taylor, many scientists have References distinguished themselves. As research limitations, we would therefore emphasize the small number of pioneers studied and the selection of application examples. For future competitiveness, an lndustrial Engineer’s collection of applicable methods and tools has to be expanded to accommodate for the capabilities of IDS. At the same time, companies must create the technical and educational basis for applying IDS in order to be able to assert themselves in the market. In addition, the multitude of requirements for an integrated and networked application of industrial data analysis in dynamic value creation networks will shape the further course of IDS research.

Literature

IISE. (2021). What is industrial and systems engineering? (IISE official definition). Institute of Industrial & Systems Engineers. https://iise.org/details.aspx?id=282

Mazarov, J., Wolf, P., Schallow, J., Nöhring, F., Deuse, J., & Richter, R. (2019). Industrial Data Science in Value Creation Networks (in German). Zeitschrift Für Wirtschaftlichen Fabrikbetrieb, 114(12), 874-877 (Concept of a Service Platform for Data Integration and Analysis, Competence Development and Novel Business Models). https:/ /doi.org/10.3139/104.112205

Taylor, F. W. (1911). The Principles of Scientific Management. Harper & Brothers Publishers.

West, N., Syberg, M., & Deuse, J. (2022). A Holistic Methodology for Successive Bottleneck Analysis in Dynamic Value Streams of Manufacturing Companies. In A.-L. Andersen, R. Andersen, T. D. Brunoe, M. S. S. Larsen, K. Nielsen, A. Napoleone, & S. Kjeldgaard (Eds.), Lecture Notes in Mechanical Engineering. Towards Sustainable Customization: Bridging Smart Products and Manufacturing Systems (pp. 612–619). Springer International Publishing. https://doi.org/10.1007 /978-3-030-90700-6 _ 69