The Evolution of Scientific Management: From Industrial Engineering to Industrial Data Science

Ever since the First Industrial Revolution, optimization measures and operational decisions in the manufacturing industry rely on quantitative and fact-based assessments. New advancements during the ongoing digitalization and globalization of nowadays world of work represent a logical and inevitable continuation of the observable trends in science and technology. Against the background of this natural development, emerging potentials through Data Science do not necessarily represent a paradigm shift, but rather a continuation of the development of Industrial Engineering (IE). In view of the currently inflated expectations with regard to Data Science’s problem-solving capacities and its promises of economic rationalization, this paper draws references to major representatives and pioneers of IE, such as Frank and Lillian Gilbreth, John Burbidge, William E. Deming and Eliyahu M. Goldratt. Using their respective field as examples, we summarize the development of IE to date. Based on current trends, this paper looks at scientific trends to outline a scope for the future evolution of Industrial Data Science.

This publication is the result of the research work of the Institute of Production Systems at TU Dortmund University.

Summary and outlook

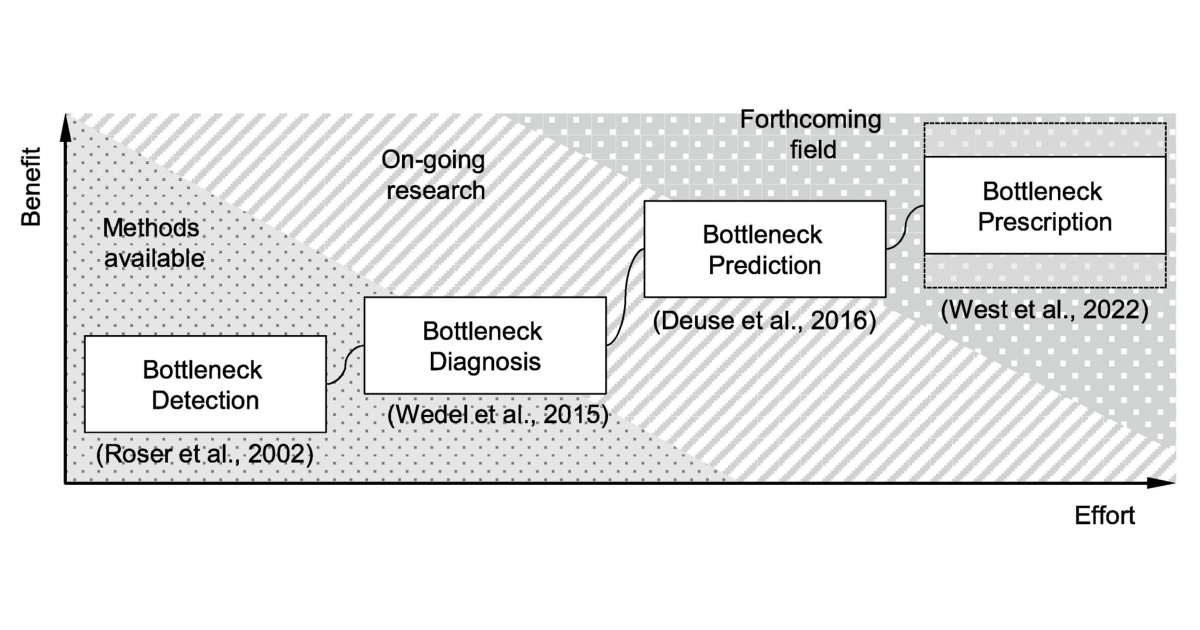

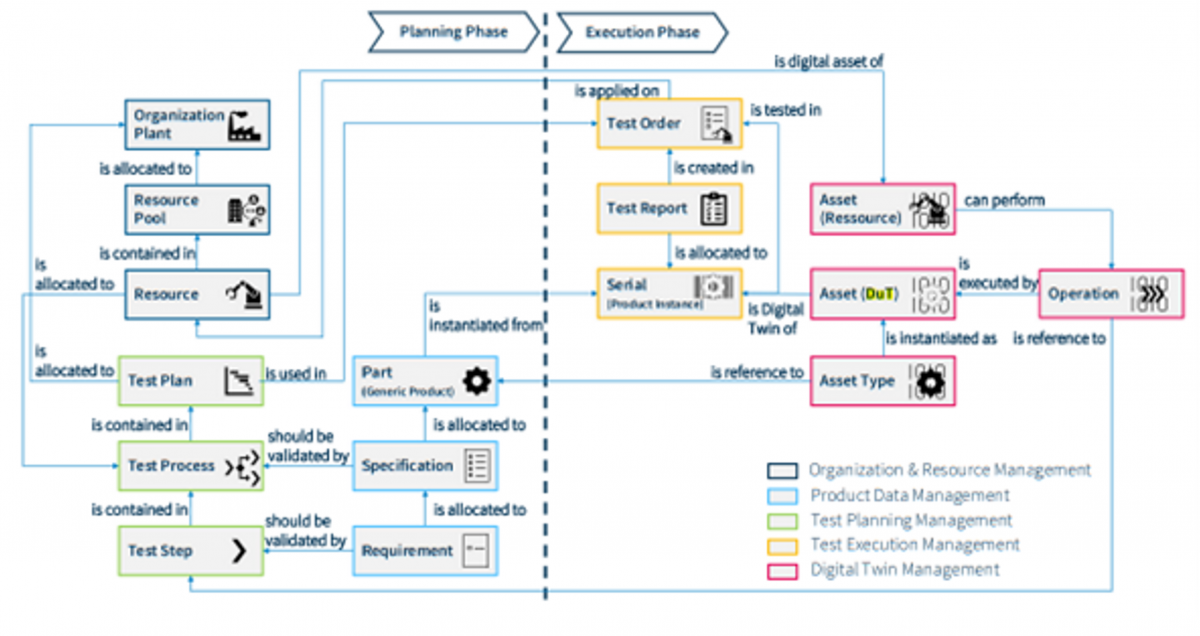

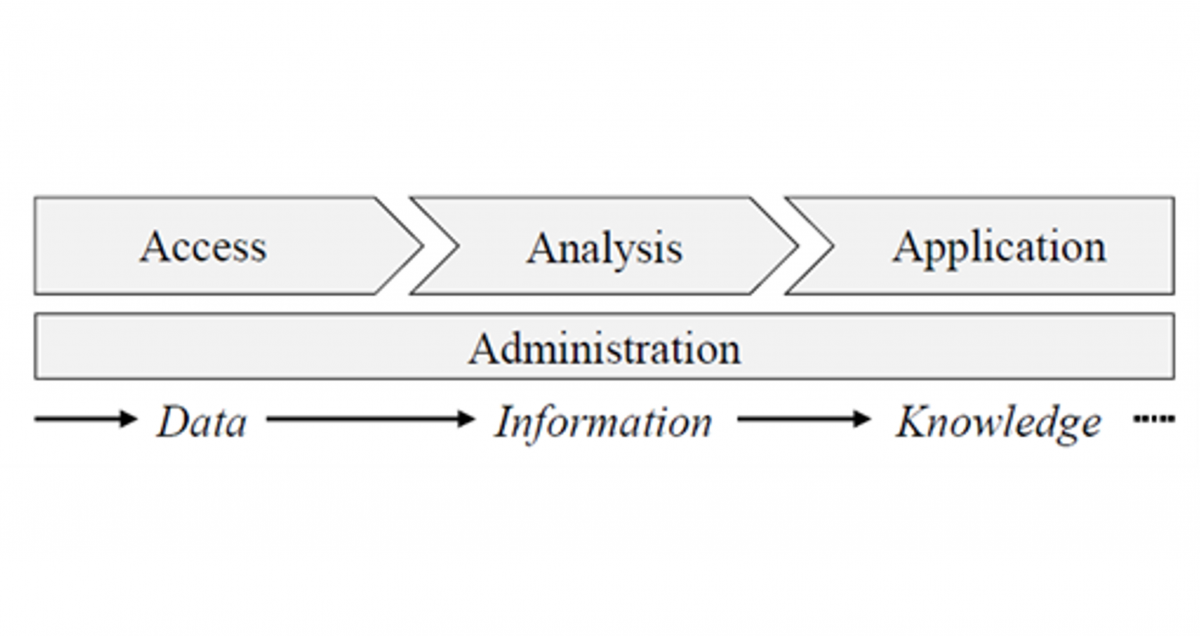

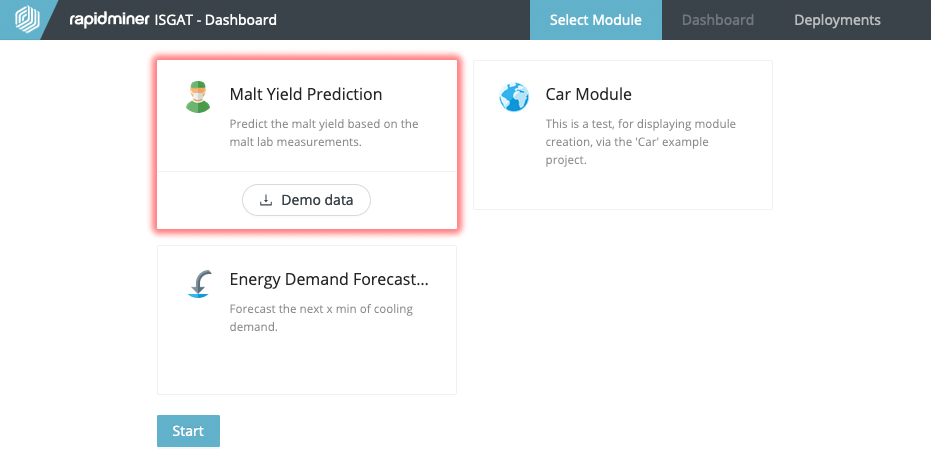

The four case studies of the pioneers of IE in this paper show the development of Scientific Management in different domains as an evolutionary process. We consider the trend towards a widespread application of Industrial Data Science as the inevitable result of a decades-spanning development process. Leveraging the growing data sources is just the next logical step in an environment that relies on fact-based and quantified decision-making. Thus, the application of Data Science in Industrial Engineering under the umbrella of Industrial Data Science will continue to grow in importance in the coming decades. At their core, manufacturing companies will continue to use the original concepts of the discussed pioneers, but increase the effectiveness through the addition of digital and data-driven methods and tools. Accessing, analyzing, applying and administrating data is going to be vital for future applications of Industrial Data Science. For future competitiveness, an Industrial Engineer’s collection of applicable methods and tools has to be expanded to accommodate for the capabilities of IDS. The multitude of requirements for an integrated and networked application of industrial data analysis in dynamic value creation networks will shape the further course of IDS research.

The complete publication can be found here: