Work report: Insights into the use case “Comprehensive, Predictive Industrial Engineering” of Volkswagen AG

Within the framework of Use Case 1 (UC1), data-driven methods and tools will be developed to support holistic productivity management in Industrial Engineering (IE). The competence portfolio of IE will be extended by methods and tools of Industrial Data Science. By implementing data-based decision support along the product development process and in the series production phase, the focus is placed more strongly on the design tasks in IE. Through the integration, processing, analysis and context-related provision of already existing data, knowledge already available in the company for productivity management will be more easily accessible.

Introduction to Use Case 1

The contribution of Use Case 1 (UC1) is the development of data driven methods and tools to support holistic productivity management in Industrial Engineering (IE). Hence, existing competencies and skills are extended to facilitate the use of Industrial Data Science. By implementing data-based decision support along the product development process and in series production, IE focuses more specifically on shaping productivity. With the purpose of making domain knowledge on productivity management more accessible all over the company, contextual data must be integrated, processed and analyzed.

For this reason, UC1 focuses on the use of Industrial Data Science to design and optimize work processes. Currently, design and optimization solutions for manual work processes in manufacturing are highly dependent on individual experience and domain knowledge. In future, automated analysis of process data will reduce the manual effort required to identify relevant data. This gives industrial engineers the ability to fulfill their design and optimization tasks more effectively and efficiently based on the automatically generated results.

Organizational framework and collaboration model of UC1

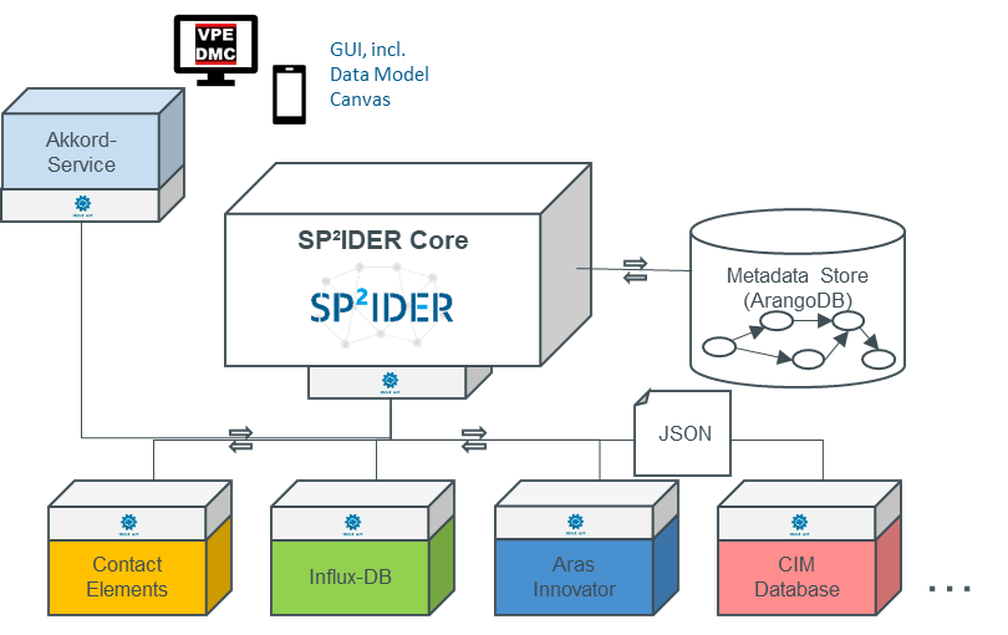

UC1 “Comprehensive, Predictive Industrial Engineering” represents one of eight use cases in the research project AKKORD. The project relies on close cooperation between research, development and application partners. The collaboration model is based on iterative development and testing, so that generated content is already validated during the ongoing project.

Volkswagen Group Industrial Engineering of Volkswagen AG is in charge of the UC1. Volkswagen Group Industrial Engineering is mainly responsible for the development of the group-wide IE strategy and suitable methods. In addition, Group IE is driving forward the expansion of its competence portfolio and thus the use of Industrial Data Science applications.

In UC1, the development of a data-based decision support is mainly carried out in collaboration with RapidMiner GmbH and the Institute for Production Systems at the Technical University of Dortmund.

However, change management is also quintessential for the successful use of data-based decision support. The cooperation between Group IE and mosaiic GmbH focuses on the development of a specific change management to increase the professional effectiveness of UC1.

A collaborative approach in UC1

Using a three-step approach intends to enable data-driven decision making:

- Developing a methodology to identify similar work systems

- Developing an automated benchmarking, which compares and evaluates similar work systems for work process design and optimization tasks

- Developing and implementing data mining methods for the contextual provision of proposals for work process design and optimization

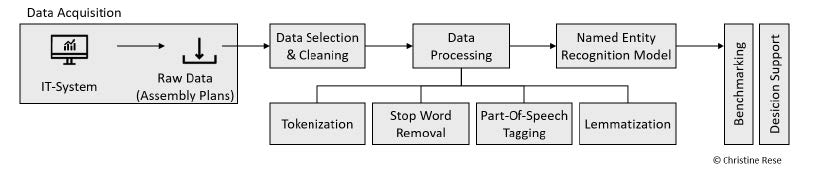

The current processing status of the three-stage concept is organized according to the following pipeline and will be implemented in RapidMiner Studio.

As part of the data acquisition, the first step was to investigate the extent to which existing information could be used for the planed analysis. The database is part of an IT system that is used to design, optimize and document manual work processes for vehicles, aggregates and components over the product life cycle.

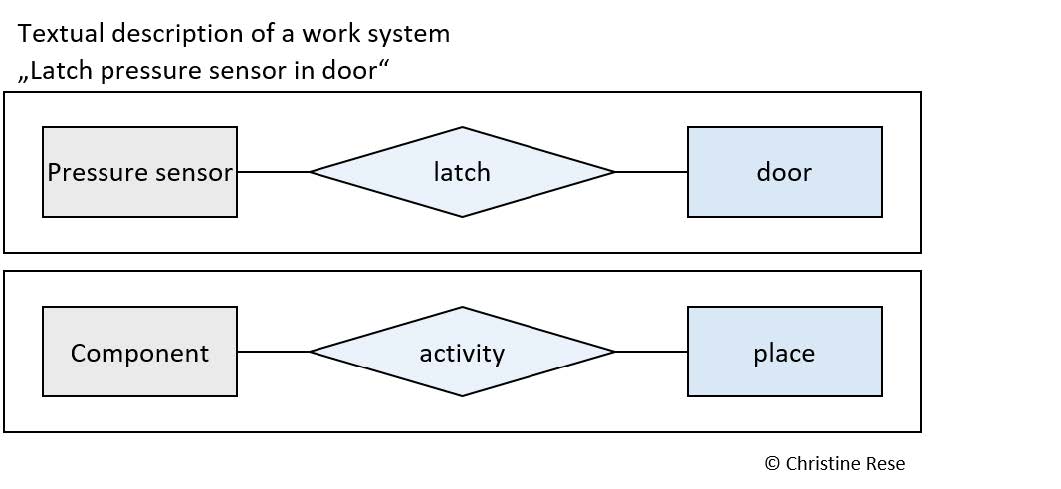

Text mining methods are used to identify similar work systems within various work processes. The work process descriptions are examined for their similarity in content. Among other things, the identifiability of individual component descriptions across language boundaries in different assembly plans was examined in more detail. It was found that the textual descriptions of the work processes can be mapped by entities.

The mapping of the textual descriptions as entities enables the identification and merging of work processes with similar content, taking into account the associated component. The assembly plan can thus be decomposed into component-related aggregated process sequences. These process sequences form the basis for the comparison of similar work systems.

In order to develop the similarity measure, further data will be included in the textual analysis in future. For example, context information on the considered work processes can be used for condensing and specifying the analysis results.

The similarity measure forms the basis for the further development of data-based decision support in the context of work design and optimization. The development of automated benchmarking and automated suggestion generation represent the next steps on the way to the implementation of industrial data analysis in IE.

Benchmarking enables the comparison of the identified processes or relevant operations. The work designer can take into account the knowledge gained from benchmarking when designing or optimizing his work processes. With the help of suggestion generation, the work designer should receive concrete situational and context-related suggestions.

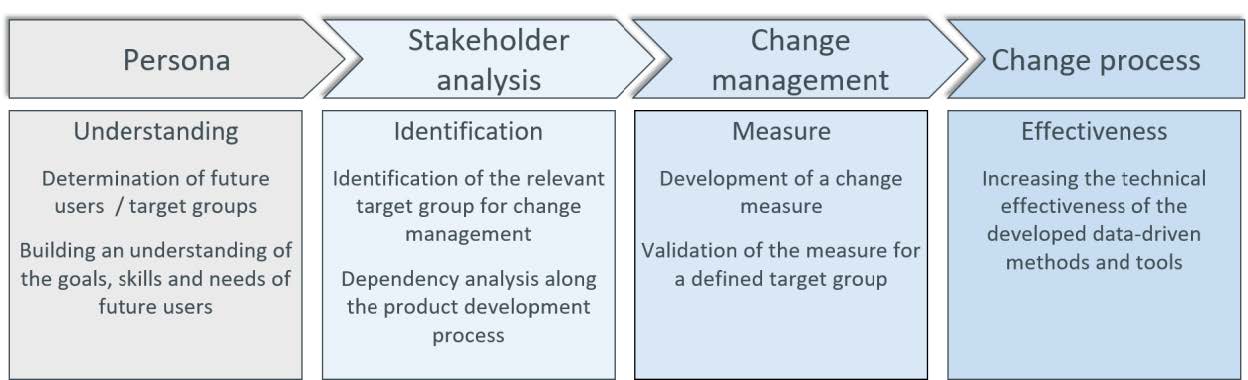

The second field of action of UC1 covers the activities for the development of a data analytics-specific change management. The chosen approach can be illustrated as follows:

The used “persona” method employs an abstract view of potential users and thus enables the derivation of concrete user requirements for the design of data-based decision support for work process design and optimization. This was followed by the identification of relevant target groups for change management. With the help of a stakeholder analysis, the identified target groups were examined with regard to the factors influence and affectedness and, in a next step, transferred to a dependency analysis along the product development process. Currently, the focus is on the development and integration of a change measure into the concept of an in-house expert forum “Industrial Data Science for Industrial Engineering”. In the course of this expert forum, it is planned to test specific change measures for data science use cases – in the future, these can also be generalized or abstracted to other use cases.

Summary and outlook on further research objectives

The similarity measure represents the first step of the three-stage process model. In the coming project year, the other two steps will be detailed and subsequently operationalized. Furthermore, the developed change measure will be validated in an internal expert forum.

Author and Contact Person: