Presentation of the AKKORD research project at the automatica trade fair 2022 in Munich.

The automatica trade fair 2022 took place from June 21 to June 24. The exhibition is considered the leading one for intelligent automation and robotics. One of this year’s trend topics of the trade fair was the digital transformation in manufacturing, which made the presentation of the AKKORD research project just right. AKKORD was represented at the trade fair by the Institute for Production Systems (IPS) with the Carrera demonstrator. The demonstrator was used to show interested visitors how the AKKORD platform enables small and medium-sized enterprises (SMEs) to apply industrial data analysis.

Classification of the Carrera demonstrator in the AKKORD reference toolkit

The AKKORD research project is divided into performance areas in which the objectives of the project are developed. A summary overview of the four performance areas in AKKORD can be found in this news article. Further information on the research project can be found in the kick-off publication and in the monthly work reports of all partners.

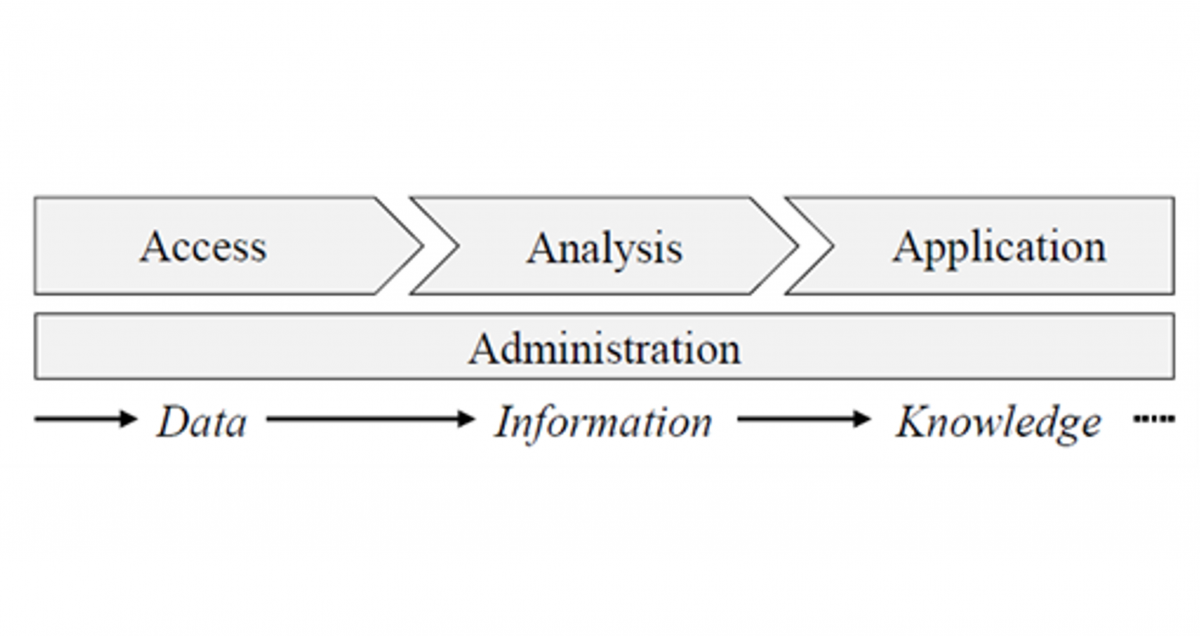

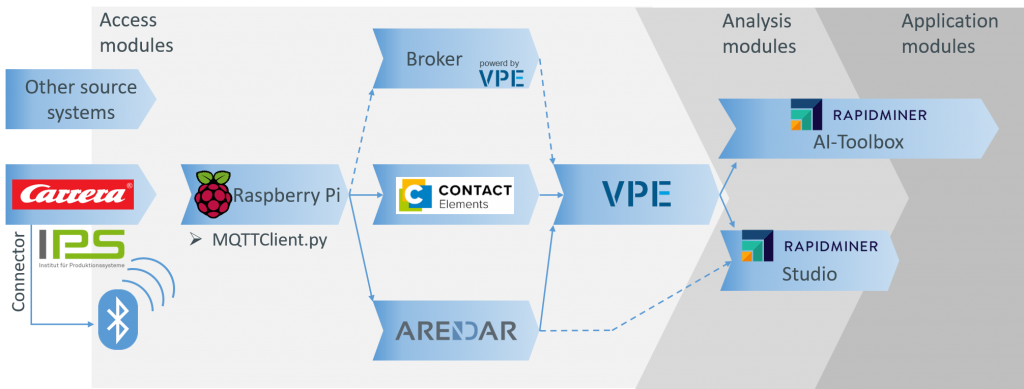

Within the reference toolkit (Figure 1), the Carrera demonstrator executes the process chain of industrial data analysis. Tangibly, the toolkit illustrates data access, analysis, and use on the AKKORD platform. The aim of the demonstrator is to present the results of the research project as straightforwardly as possible. At the same time, interested parties should be shown how holistic and powerful the application of the AKKORD platform is.

Figure 1: AKKORD reference toolkit

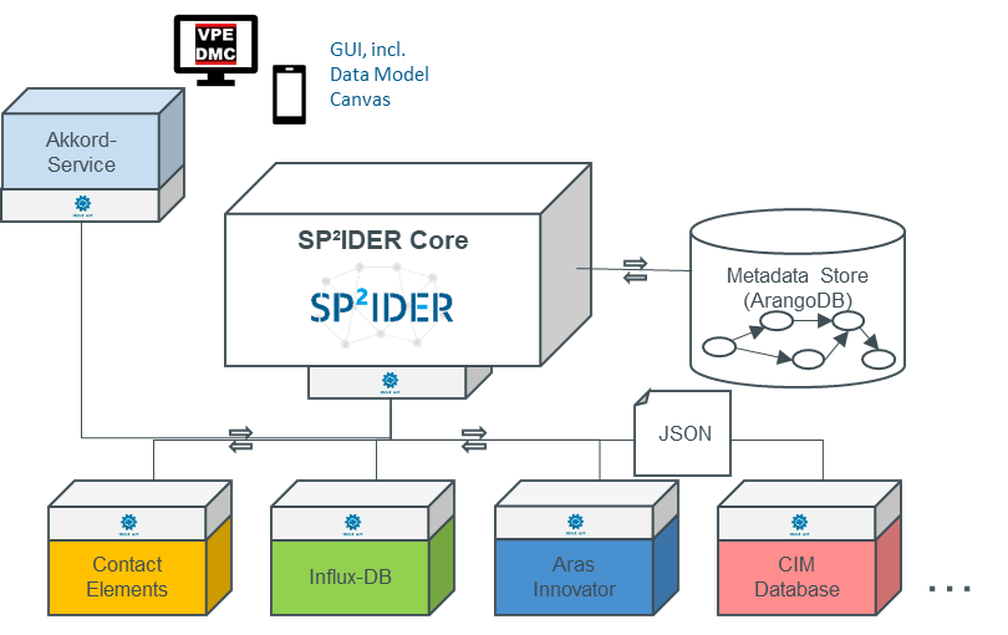

Figure 2 shows the system architecture for the Carrera track use case. In the following sections, the individual steps of the architecture are explained.

Figure 2: System architecture of the Carrera demonstrator

Individual data access possible through modular system

The data access of the Carrera track is done via a Bluetooth interface. Using a Python script, the timestamps and vehicle data are sent to the ARENDAR, as well as to Contact Software’s data backend, via an MQTT interface. The two-pronged approach to data access illustrates how versatile the AKKORD platform’s modular data access is for industrial customers.

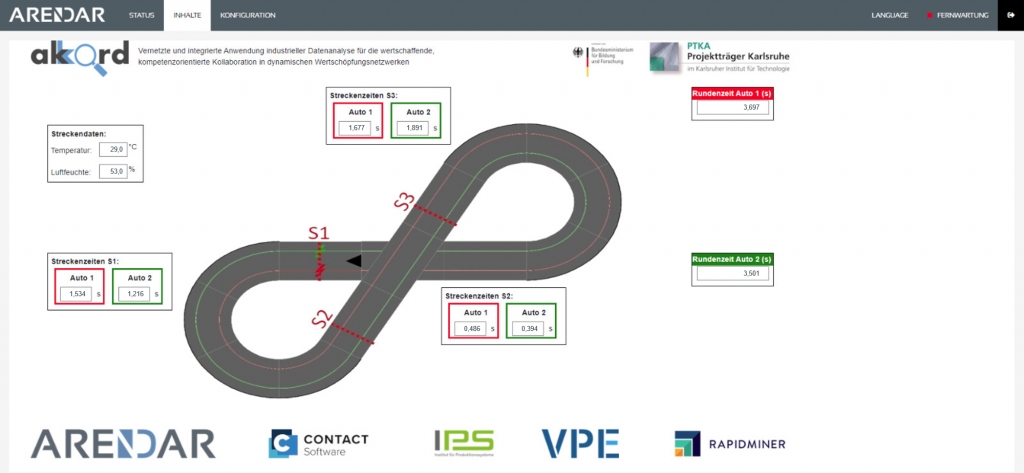

The ARENDAR referred to is a highly secure IoT gateway that can directly perform evaluations and display dashboards in addition to data processing (Figure 3). It offers analog, digital, LAN and wireless inputs, so every data interface is covered by it. On the other hand, Contact Software stores data in a data backend. In the backend, multiple source systems can be connected and subsequently flexibly linked and routed out via the Data Model Canvas.

Figure 3: ARENDAR Dashboard

Simple analyses due to low programming effort

Data analyses are performed by the AI toolbox developed by RapidMiner (Figure 4). A dynamic connection between the data backend and AKKORD AI Toolbox is established, for example, via a URL interface. Within the AI toolbox, users are shown existing data analyses. For the Carrera track, there are already analysis modules for determining the race winner, for calculating the fastest lap, and a speed module. With just a few clicks, the data from the backend is linked to the selected module via the Data Assistant (for more information, see this work report). The corresponding data schema of the analysis module shows which attributes are needed. By simply connecting the attributes with the original attributes of the module, the required data schema is quickly generated. Now the analysis can be performed and the user gets the appropriate dashboard for the performed analysis. In this way, Industrial Data Science (IDS) analyses can be carried out individually and easily without much effort.

The network effect enables SMEs to use existing modules. Accordingly, they do not have to create their own analyses, but can make use of the reusability. By loading own data and additionally simply changing the parameters, each user creates his individual analysis with little effort.

Figure 4: AI-Toolbox automatica 2022 © MHI e.V.

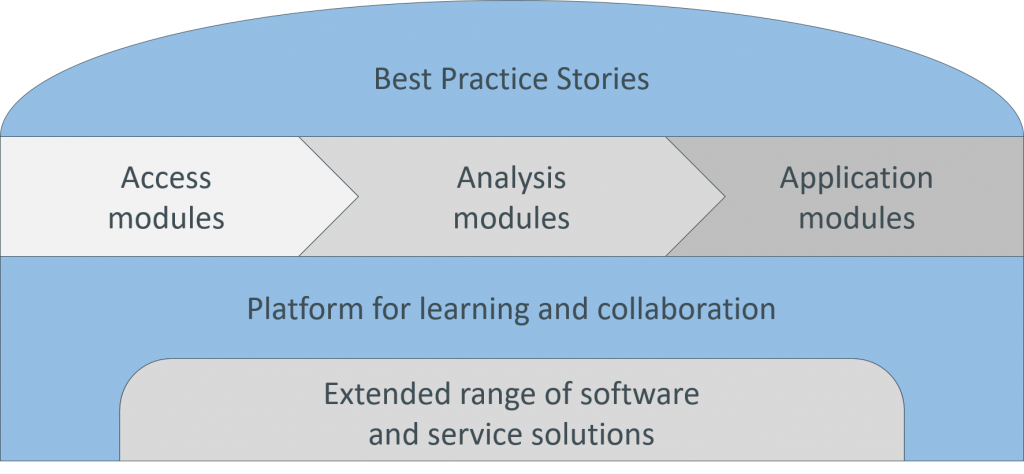

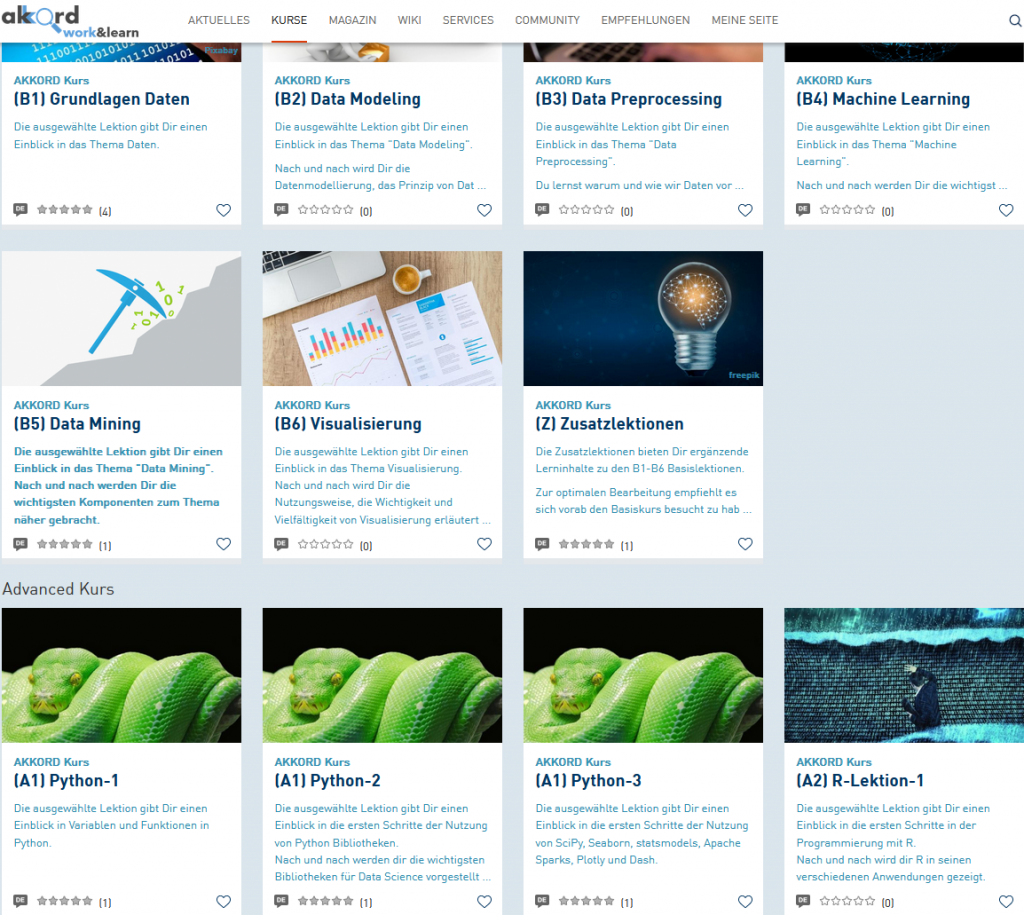

Work & Learn platform empowers users to use modular data analytics

At the automatica trade fair 2022 in Munich, IPS also presented the collaboration and learning part of AKKORD’s platform. This part empowers users to use the AKKORD Work & Learn platform (Figure 5). Each role in IDS projects is offered an individual learning path. For example, dashboard users are offered low-threshold modules on fundamentals topics. Analysts, on the other hand, get the opportunity to educate themselves on advanced content such as Python courses. This work report contains more information about the AKKORD Work & Learn platform.

Figure 5: Work & Learn Platform

Summary and outlook

Overall, the trade show appearance at automatica 2022 was very successful for AKKORD. Numerous trade fair visitors from the industry could be introduced to the platform. Currently and in the future, further presentations of the AKKORD platform by the demonstrator are planned. With the help of the Carrera demonstrator AKKORD makes industrial data analysis tangible for everyone.

Many thanks to the Scientific Society for Assembly, Handling and Industrial Robotics – MHI e.V., which provided the booth to the Institute of Production Systems and took over the organization for their members.

Author and contact person: