Work report of Use Cas 4 and 5 (WP 4 and 6) – Data acquisiton within AKKORD

This report provides an overview of the current status of the use of the ARENDAR edge gateway in various scenarios of the AKKORD research project.

UC 4: Challenges in production

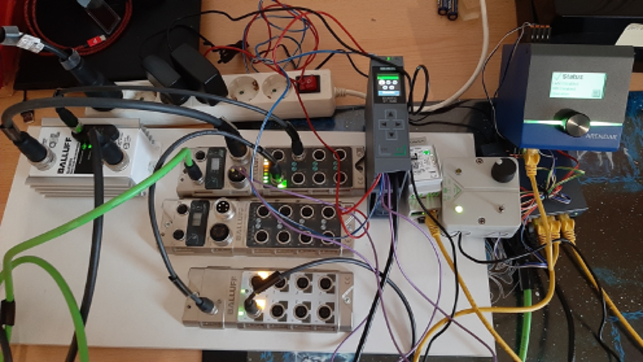

In Polymerge’s Use Case 4, the problem in the area of data acquisition is that the data for evaluation must be read out from the process at a higher frequency than the integrated PLC could provide it. Here, Arendar IT-Security came up with a plan for a faster data acquisition. This involves hooking up to the IO-Link master in the process with a switch and a class 2 Profinet gateway. The ARENDAR edge gateway would then access the data from the Profinet gateway via MQTT. To test this path, suiting components were identified, procured and integrated into a test scenario together with the ARENDAR (see Figure 1). All components were configured accordingly and data acquisition and transfer were planned to be tested. In addition, a TIA program was created that cyclically accesses the sensors.

Figure 1: Testscenario for data acquisition in Polymerge’s use case

Unfortunately, so far no confirmation of the idea could be reported. Due to an irreparably damaged component in the scenario, which cannot be replaced due to current delivery problems of the manufacturer, it was necessary to switch to the acquisition of internal sensors of the power supply in the test scenario instead of external sensors. Here, an error was discovered in the manufacturer’s software, which currently impedes further progress.

UC 5: Second prototype of the learning station

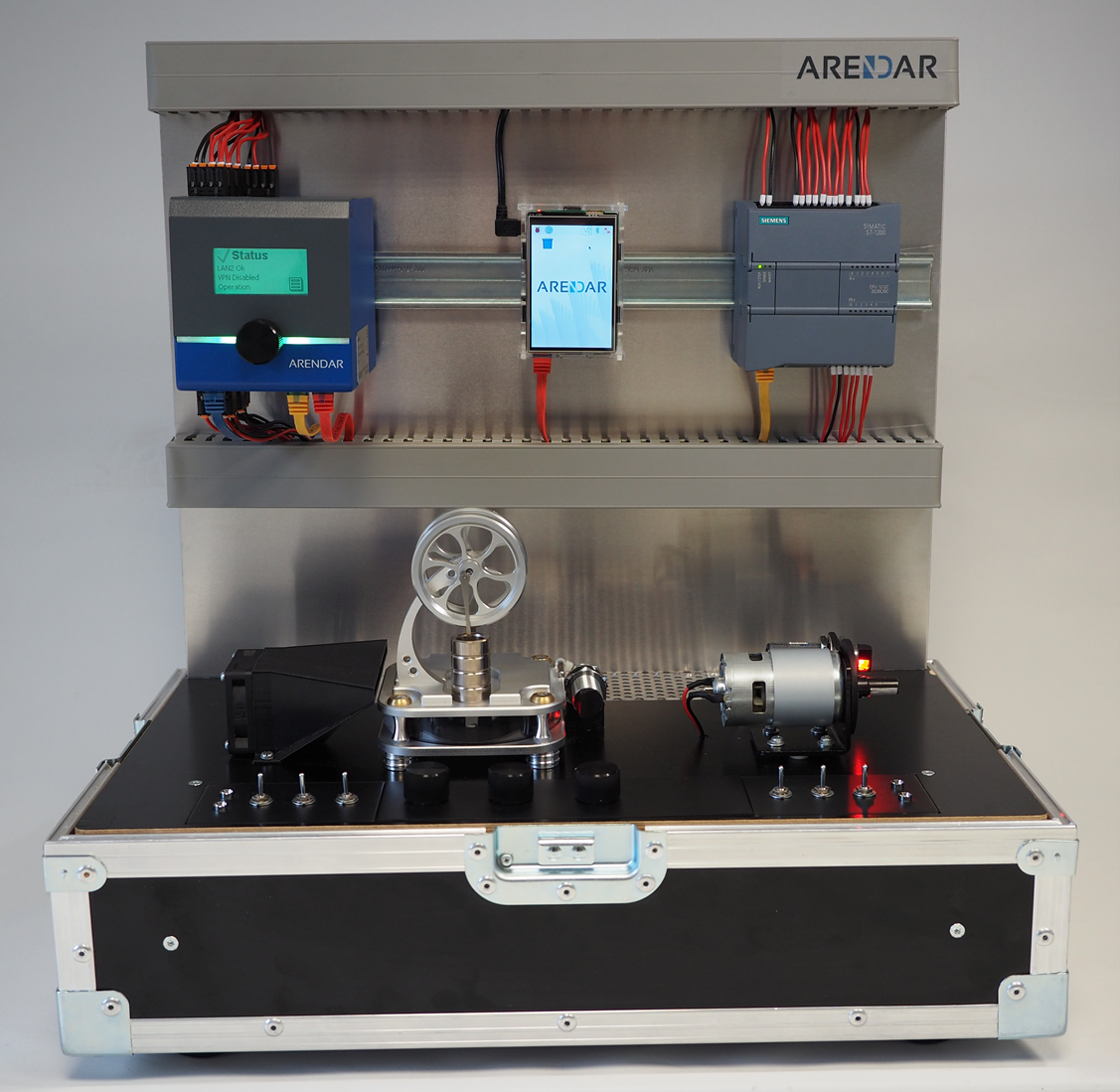

In the area of competence development, the first prototype of the developed learning station was extended. The biggest obvious change to the station compared to its predecessor (cf. description in the first work report) is the specially designed and 3D-printed cooling system for the Stirling engine (see Figure 2). The cooling solves the problem that during longer operation the upper plate heats up so much that the motor comes to a standstill (it only runs if there is a sufficient temperature gradient between the upper and lower plate). Cooling also provides additional practice scenarios in terms of control algorithms. Furthermore, additional sensors and potentiometers were integrated in order to be able to collect more values.

According to the changes in the station, the PLC programming, the visualization, the ARENDAR configuration and software had to be adapted. In the PLC, this resulted in a complete expansion of the control and the addition of cooling, resulting in two control loops for the Stirling engine: heating and cooling. In the first prototype, the electric motor was operated by a rotary knob. In the second prototype, the speed can be controlled via the PLC as an extension (PWM control). This makes it possible to operate or control the motor via the PLC and from outside via the ARENDAR. In addition, further changeover switches were connected to the PLC, which also provides more scope for use case scenarios.

Figure 2: 2nd prototype learning station

The Chair of Vocational Education in Technical Subjects (BtF) is currently working on a learning concept for the use of the station in vocational schools.

Demonstrator: Carrera-racetrack

For the use of the ARENDAR in the Carrera track demonstrator, research was first done on the communication of the ARENDAR with the track. A Python script for controlling the control unit was found. Furthermore, data transfer from the ARENDAR to Contact’s software via MQTT was enabled and an ARENDAR was made available to both the Institute for Production Systems at the Technical University of Dortmund (IPS) and the Chair of Virtual Product Development at the Technical University of Kaiserslautern (VPE) for testing purposes and for use in the demonstrators. In addition, the gateway was prototypically upgraded to output data to an Influx database.

In this demonstrator, the ARENDAR is intended to capture additional, external sensor data. Thus, the topic “retrofitting” can be addressed with the demonstrator.

Author and contact partner: