Seventh Consortium Meeting in Virtual Space at the Volkswagen AG Roadshow

The focus of the seventh consortium meeting on 15.10.2021 was the presentation of the results from the use cases. A stimulating digital interaction took place in the virtual meeting environment of the Volkswagen AG.

Presentation and interaction in the virtual environment

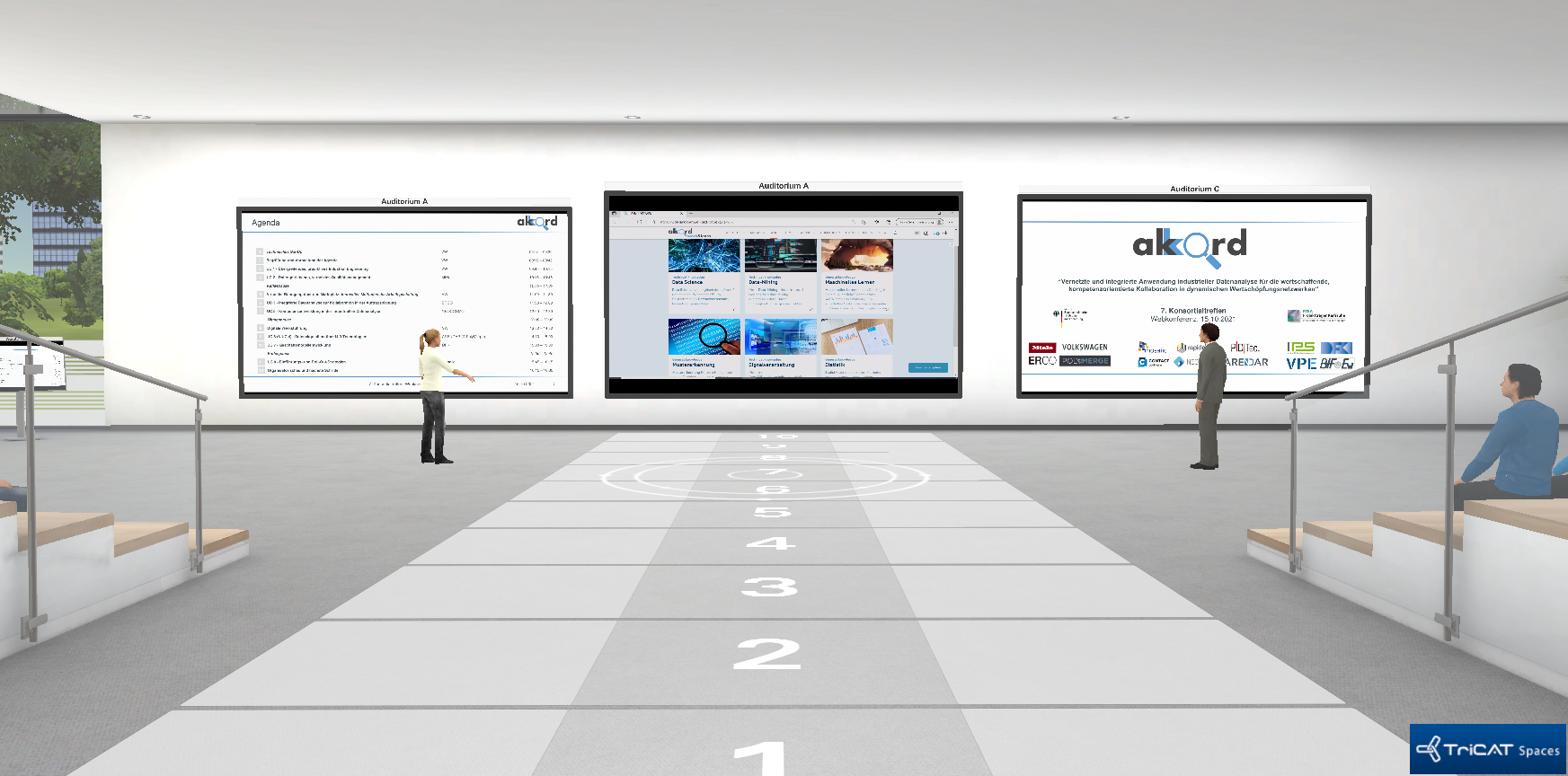

Due to the still uncertain pandemic situation, the seventh consortium meeting was again a digital meeting. The hosting partner for this meeting was the Volkswagen AG. The consortium gathered in the virtual environment TriCAT Spaces. Using virtual characters, the participants moved through the environment and interacted with each other. In the spacious plenary hall, the application partners presented their use case results (Figure 1). The consortium was then able to question and discuss the results, just as in a real environment.

Figure 1: Seventh consortium meeting in the TriCAT Spaces virtual environment.

The highlight within the virtual environment was the virtual exhibition area. The Volkwagen AG presented its vision for further development of industrial engineering. Among other things, the topic “How does the work of industrial engineering change through the use of industrial data science methods” was discussed. Figure 2 shows a section of the exhibition area.

Figure 2: Exhibition center of the Volkwagen Roadshow of Volkswagen AG

Presentation of the results of the Akkord Use Cases

The main focus of the consortium meeting was the presentation of the results of the eight Akkord Use Cases. Here is a short summary of the results with links to the content of the use cases:

- UC1 Volkswagen AG: Automated analysis of process data to avoid efforts for manual comparisons and research as well as multiple solution development

- UC2 MIELE: Step-by-step expandable, efficient and holistic reporting and analysis system that creates transparency about the quality situation and focuses on potentials for quality improvement and optimization of products and processes in a differentiated, user-specific manner.

- UC3 ERCO: Integrated order forecasting by enriching forecast models with data from social media, the web, and the ERCO-Homepage

- UC4/6 Polymerge/Arendar: Optimization of welding quality by means of industrial data analysis

- UC5 Neocosmo: Creation of the work&learn platform for competence development in the field of industrial data analysis

- UC 7 DFKI: Use of online store and social media data to derive conclusions about the business model with regard to threats and potentials

- UC 8 mosaiic: Definition of a modular process model to support the introduction of data analytics in the triad of people, technology and organization

Virtual plant tour at the Volkswagen plant in Wolfsburg

Another highlight of the consortium meeting was the virtual plant tour at the Volkswagen plant in Wolfsburg. Within one hour the plant was presented in an exciting tour from the press shop to the delivery. The consortium got a good impression of the size of the plant and the importance of the location for the region.

At this point, the consortium would like to thank the Volkswagen AG once again for the successful planning of the seventh consortium meeting.